UltiMaker

The ultimaker is the biggest printer here in the CID and has the biggest build volume. It is also in my opinion the easiest to use. These guides are used to print with this printer:

The ultimaker is the biggest printer here in the CID and has the biggest build volume. It is also in my opinion the easiest to use. These guides are used to print with this printer:

To upload files to the Ultimaker first get the stl, obj, or other 3D file type and open it with UltiMaker Cura either through opening through File Explorer or dragging the file into the UltiMaker Cura application.

Once the file loads in, you can move it around the buildplate and change it to your likings, or upload more files by dragging them into the application window.

To move the print around the print bed, first click the item you wish to move, then click the (

Once that happens you can either move it on the main axis by dragging those arrows, or just grab and drag the object to wherever you want it.

You can also set it’s exact position with the menu that appears next to the (

There you will also see two checkboxes, Lock Model and Drop Down Model.

Lock Model makes it so the model cannot move other than by changing the numbers in the menu, dragging the model or arrows will no longer move it .

Drop Down Model makes it so the model automatically moves its lowest point to be touching the print bed, and it cannot be moved upwards, but can still be moved downwards. Keep in mind that anything shown below the print bed will not be printed.

It is recommended to keep the Lock Model unselected and Drop Down Model selected.

To scale your object, select the object, then select the (

You can grab any of the three to stretch the object in the direction of that line, or instead grab the central box to stretch in all directions equally.

Again a menu will pop up with certain options. The text boxes allow you to set the length, width, or height of the object by measured size or percentage of the original model.

There you will also see two checkboxes, Snap Scaling and Uniform Scaling as well as a rewind icon.

Snap Scaling makes it so the object will snap between set sizes.

Uniform Scaling makes it so all the axes will scale uniformly, meaning any change to one axis will be matched in the other two to keep the proportions of the object the same.

The rewind icon will set the object to its original dimensions.

It is recommended to keep the Snap Scaling unselected and Uniform Scaling selected unless you intentionally want an of proportion model.

To scale your object, select the object, then select the (

You can grab these rings and rotate them to rotate the object how you would like it to print. Keep in mind where the back of the bed is, signified by the lip where it is written Ultimaker S5.

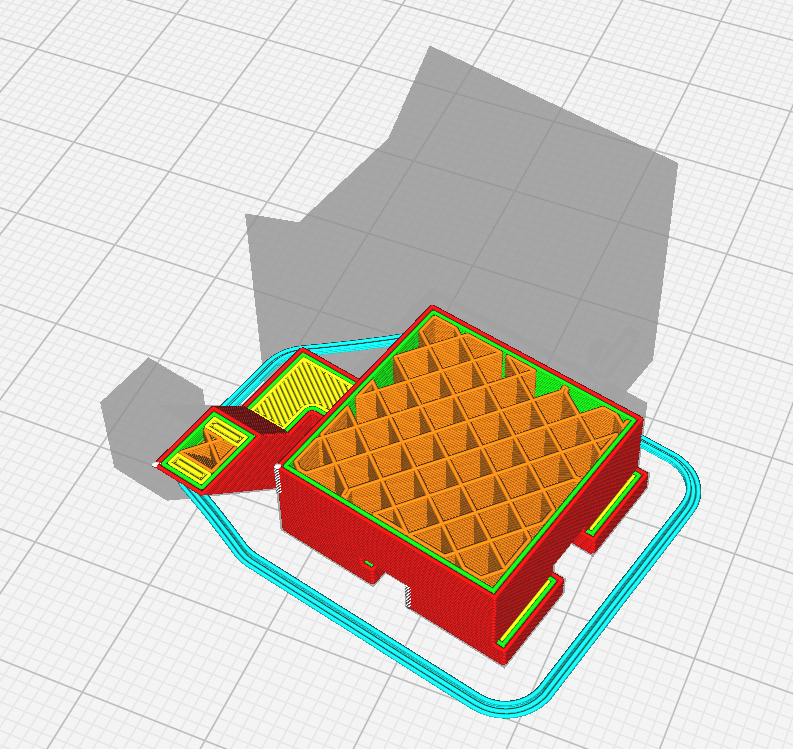

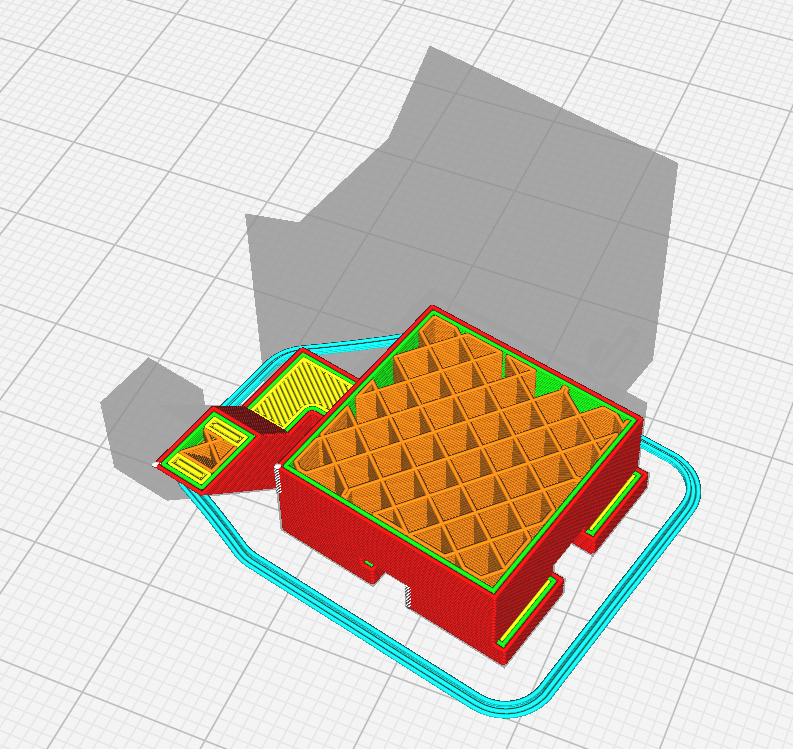

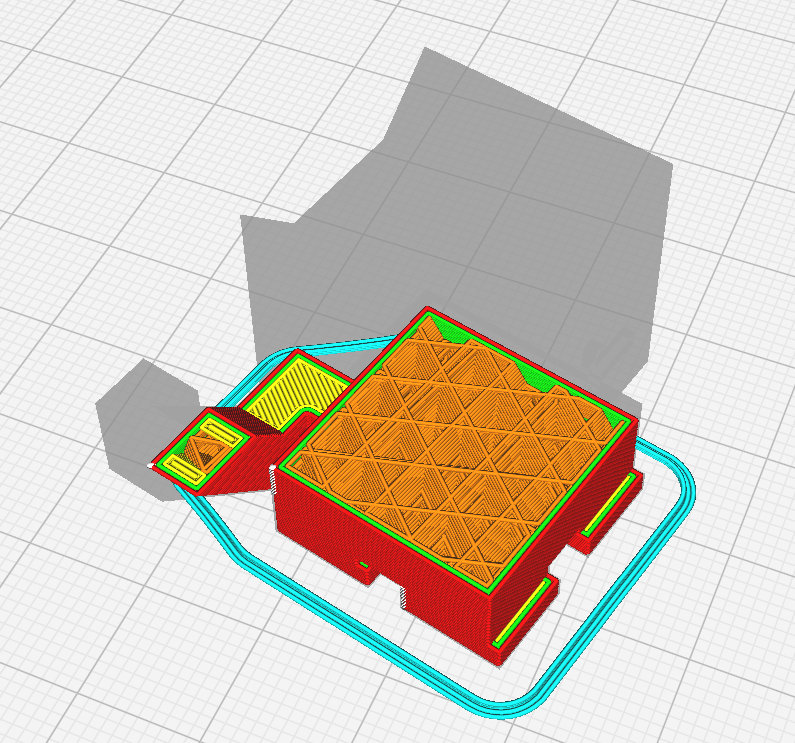

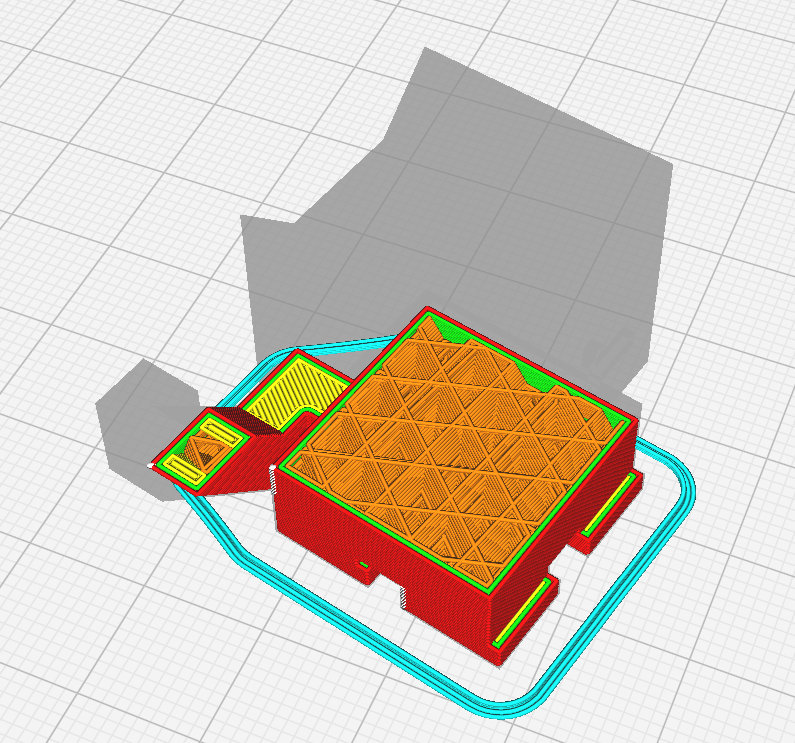

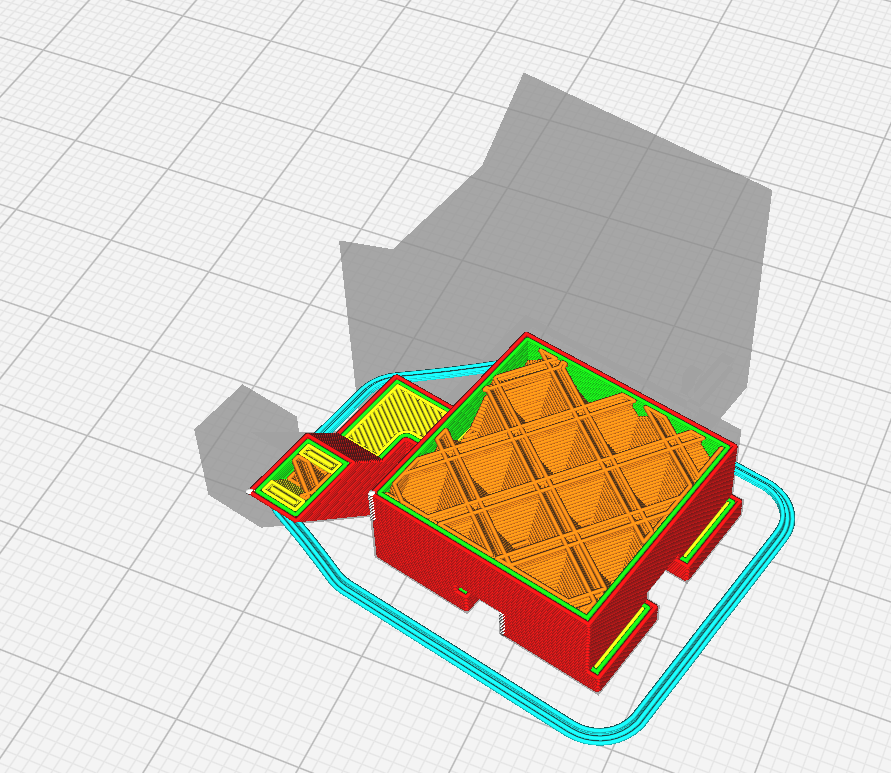

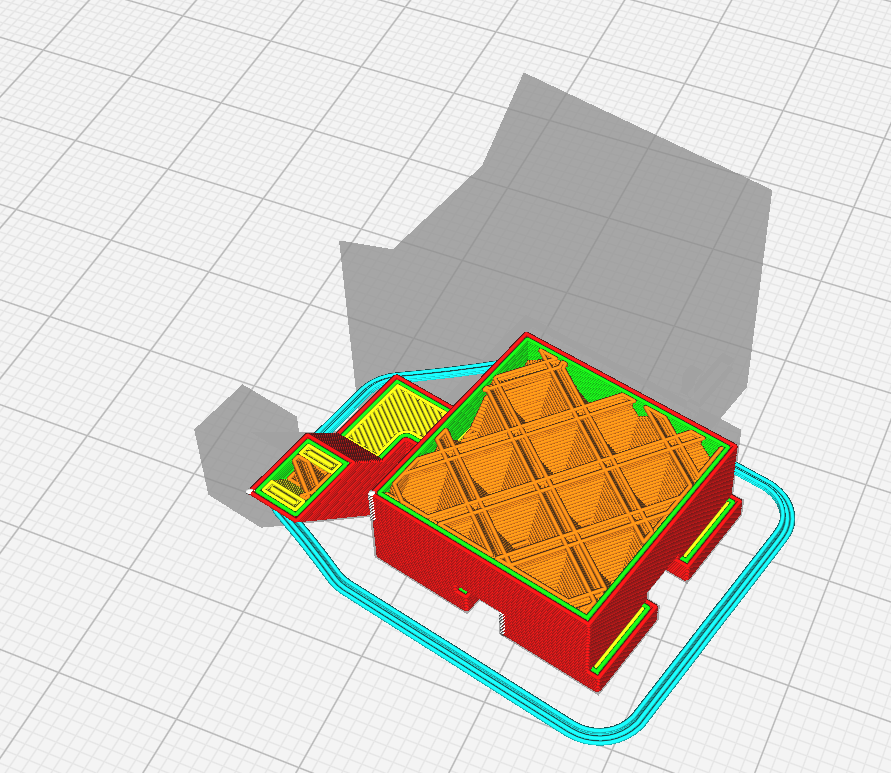

It is recommended to rotate the object so that the least amount of overhang is achieved:

And the maximum amount of the print is touching the build plate, shown by the light blue highlight:

Again a menu with certain options will also appear next to the (

The rewind icon will return the object to its original orientation.

The (

The (

Snap Rotation makes it so the print will only rotate in multiples of 15 degrees.

It is recommended to keep Snap Rotation selected unless a particular angle is needed.

When you select the (

Clicking any of these arrows will mirror the object as if there was a mirror that the arrow was pointed directly into.

When you click the (

The first icon is the default, and will follow the print settings that you set.

The second prints as if is is support for a different model, which will follow the support settings that you set.

The third will deal with overlapping objects, which is much more complicated, and a full description of the options can be found here: https://support.makerbot.com/s/article/1667417981430.

The last will remove all supports in the volume of the object, but will not print the object itself.

The (

To use this, click the model you want to remove supports from, click the (

The Ultimaker can print two materials in the same print, simply click the object and select which of the two extruders you wish to print from.

Once you are happy with the object’s placement, move to the Printer Settings section.

Once you have your object oriented as desired, move to the print settings menu.

There you will see lots of options, which I will briefly review here.

Firstly you will see a list of Profiles. These are the easiest way to select your settings.

Balanced strikes a balance of productivity, quality, strength, and accuracy. Use this for general projects.

Visual prioritizes the outwards appearance to optimize visual properties. Use this for projects that need to look good.

Engineering prioritizes accurate tolerances, and mechanical strength. Use this for projects will moving parts or that need to be stronger.

Draft is for models that are prototypes or not particularly valuable. Use this for testing and quick prints.

Resolution will change the thickness of every layer. The bigger each layer is the faster the model will print, but the worse it will look and function. It’s recommended to use Fine for good visual quality or Fast for speed and basic functionality.

Below it may say “Recommended settings for _____ were altered”. Clicking the rewind icon will reset to recommended settings and the floppy disk icon will save the current settings as a new preset.

This slider will allow you to dictate how much of the interior of the print is filled in, with 0 meaning no fill, and 100 meaning completely full.

anything down to 10% will be self supporting enough, although 20% is recommended for nearly every print. 70% is the absolute maximum you need to go for a high strength print, however this should only be used if extreme strength is needed.

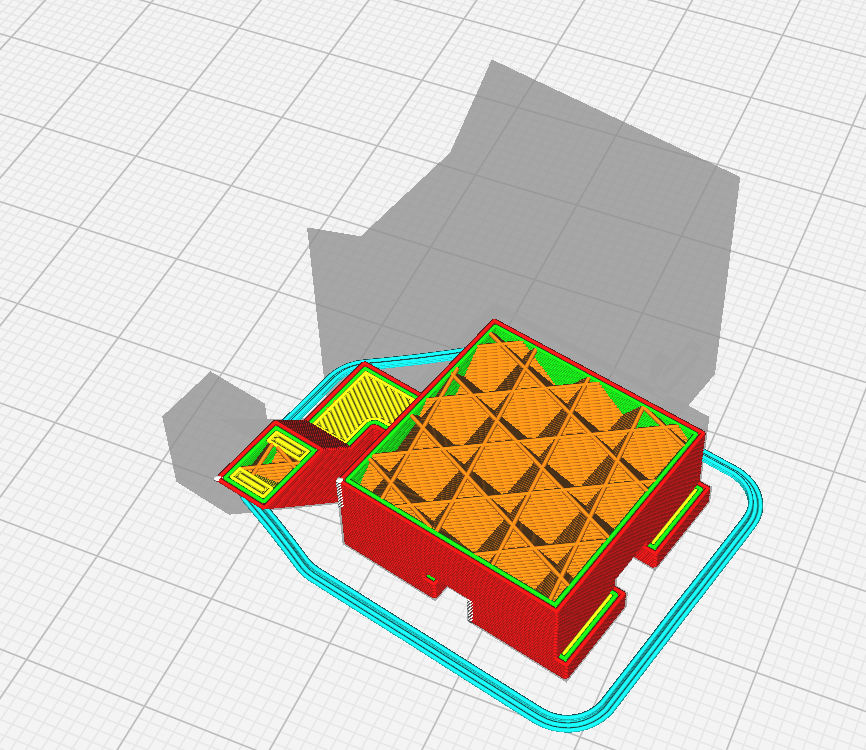

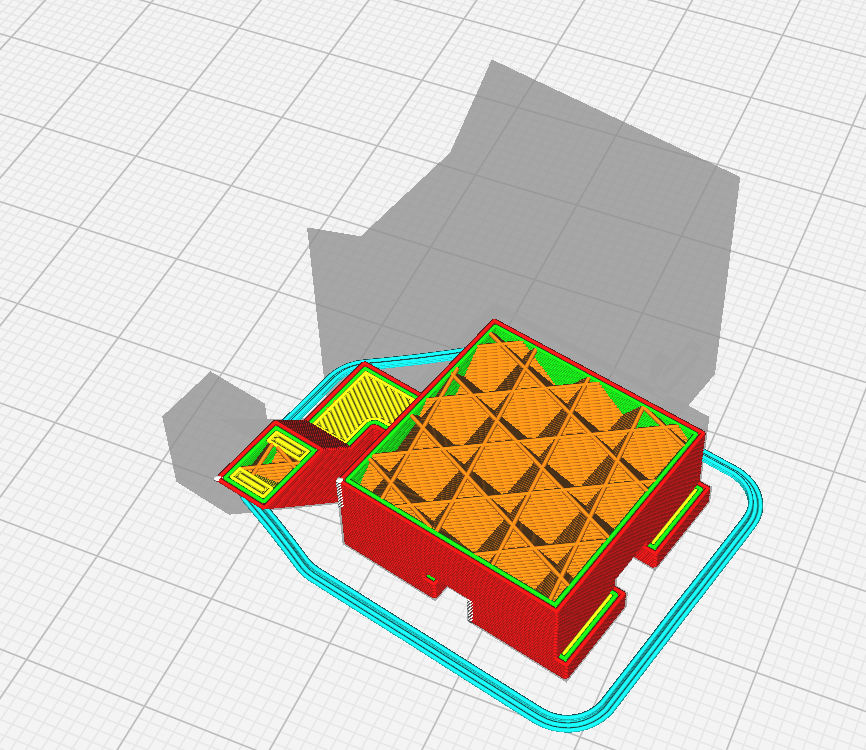

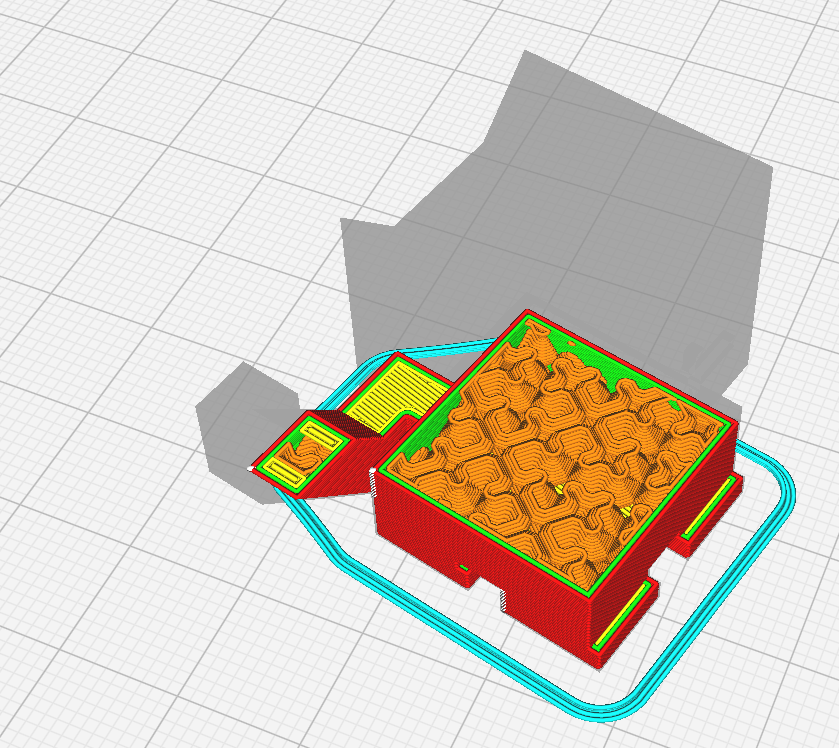

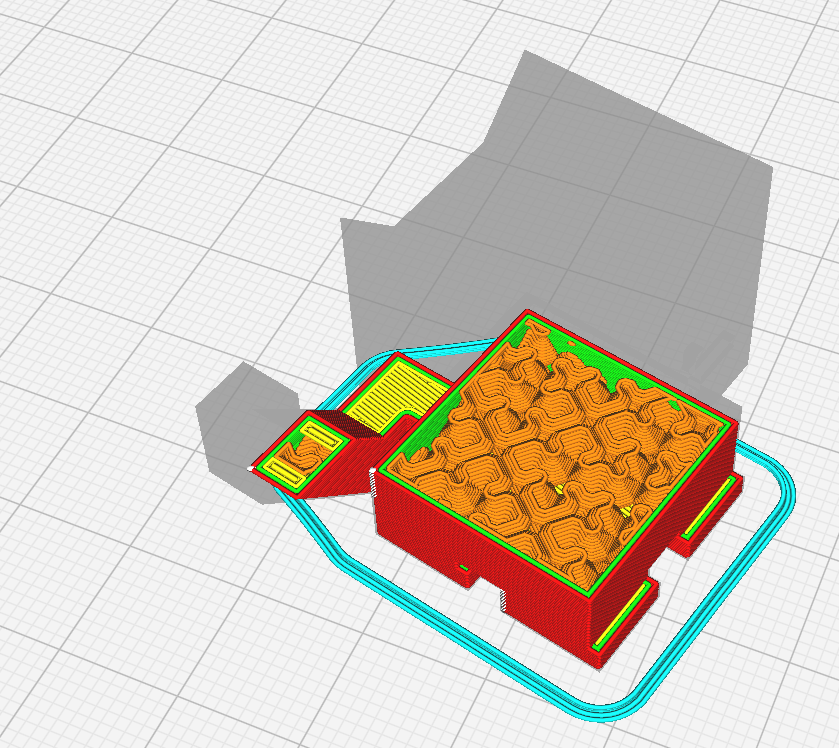

This allows for a selection of how the infill will be created, with options shown below:

Grid

Triangles is the recommended setting but this choice has little effect on the overall print.

This lets you set the thickness of the outer shells of the print, with the first box designating the side walls, and the second designating the top and bottom.

Supports are how the printer helps overhangs print, as the printer must always work from bottom to top and cannot print without a surface to print on. Support can be selected and deselected, but is recommended to use whenever there are overhangs or floating objects in your print.

This box allows for two choices, Normal and Tree.

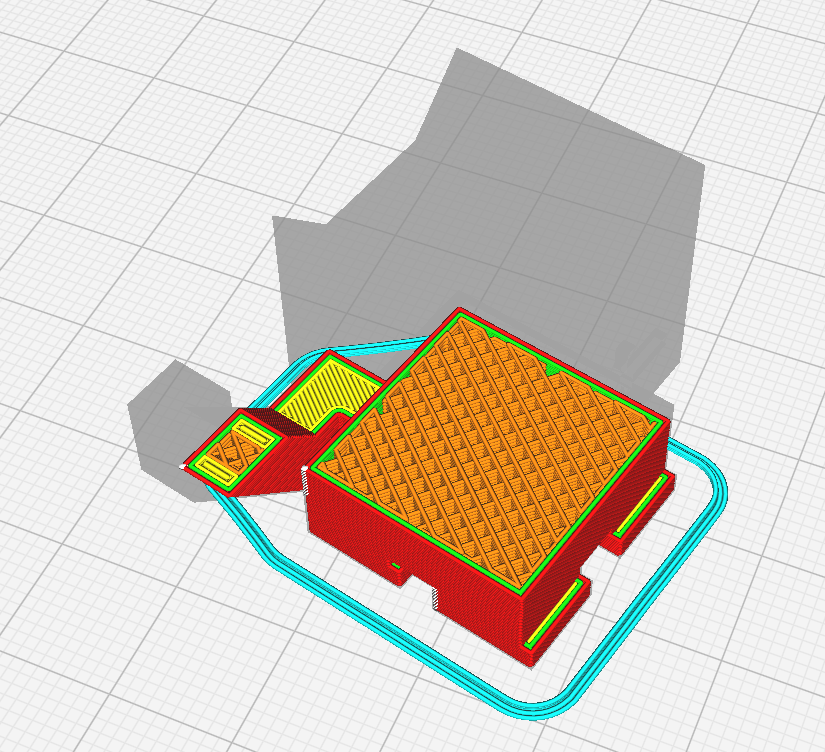

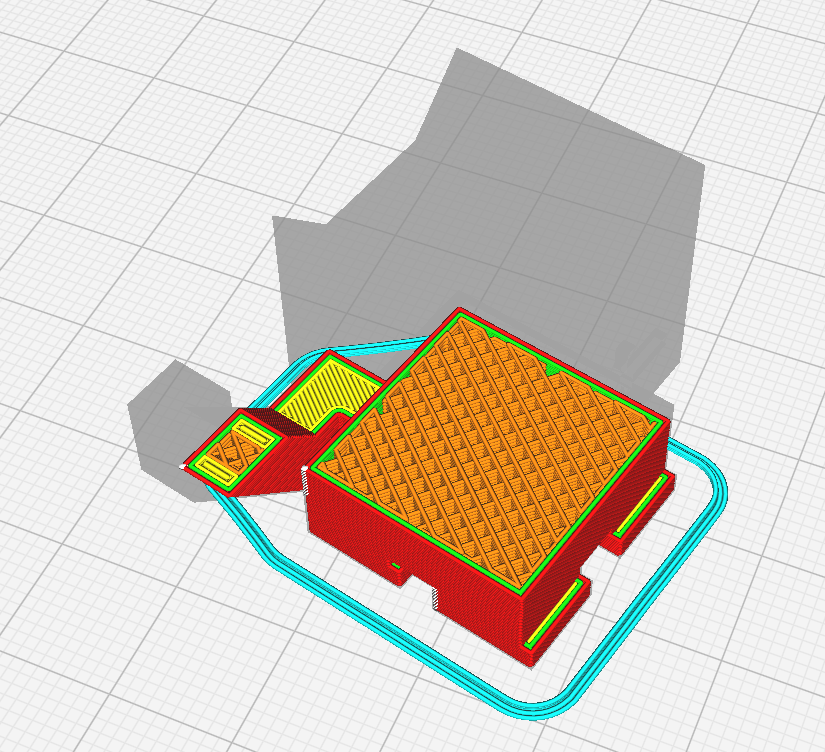

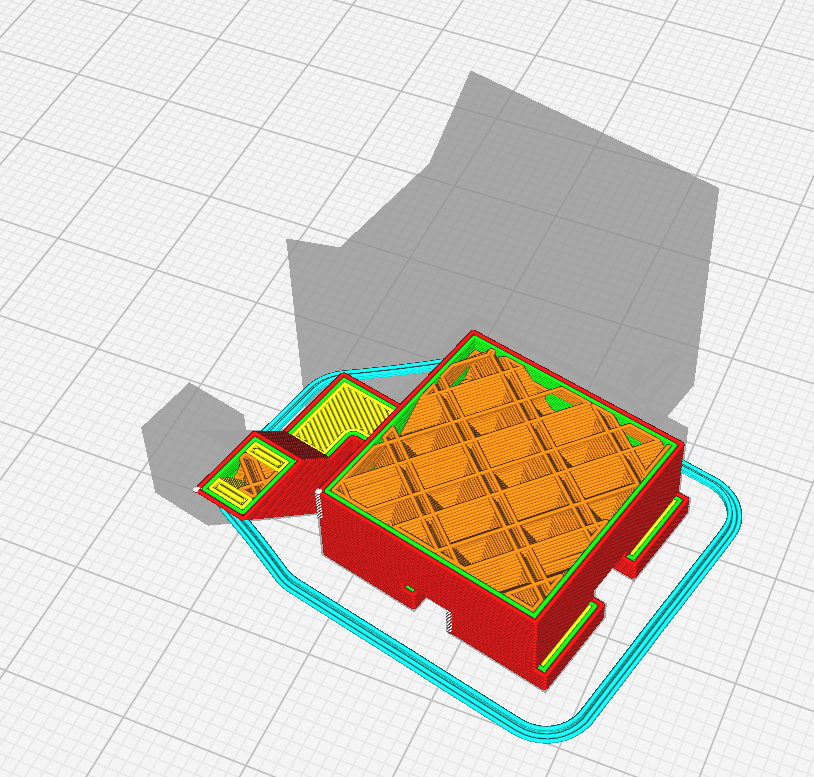

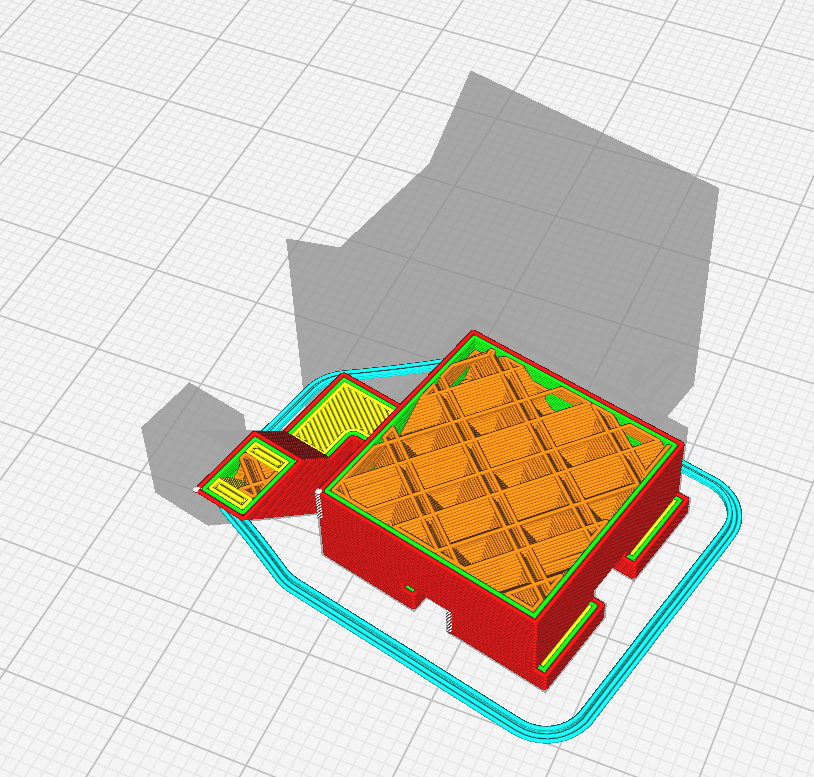

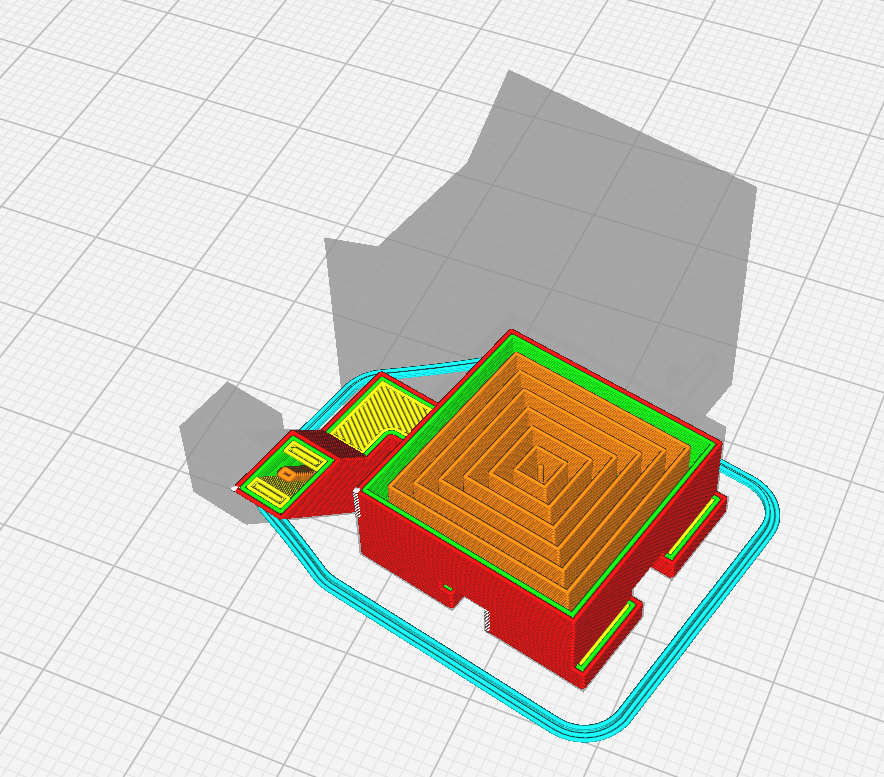

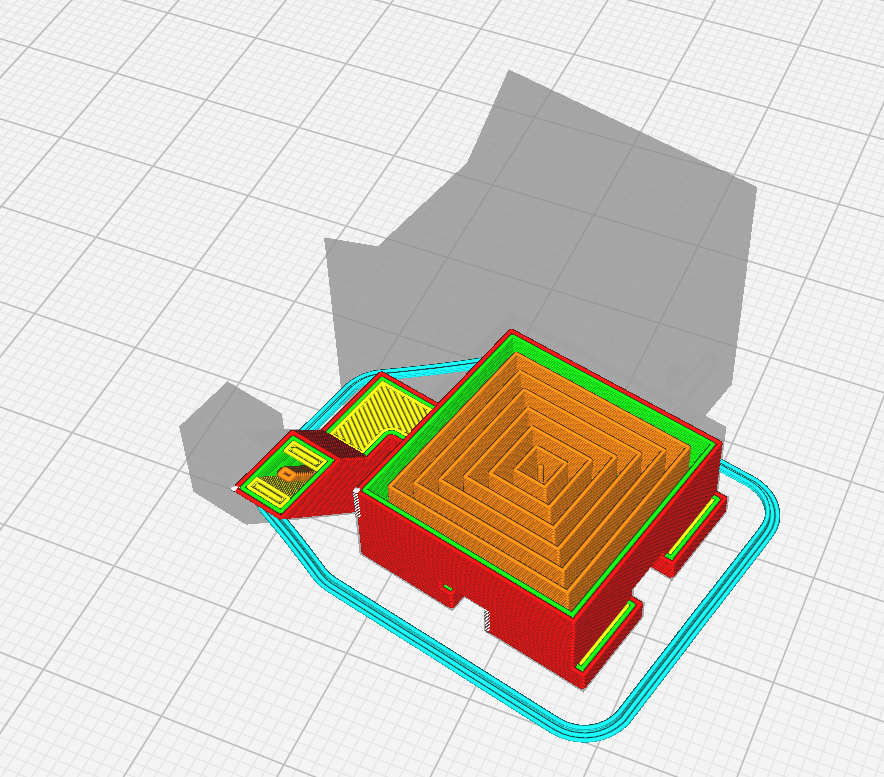

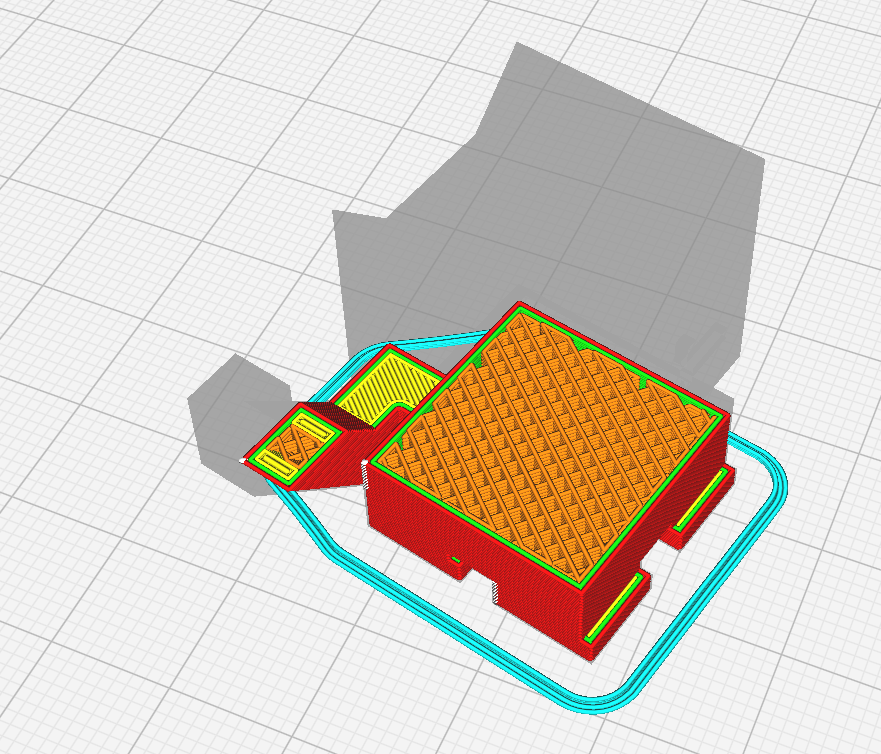

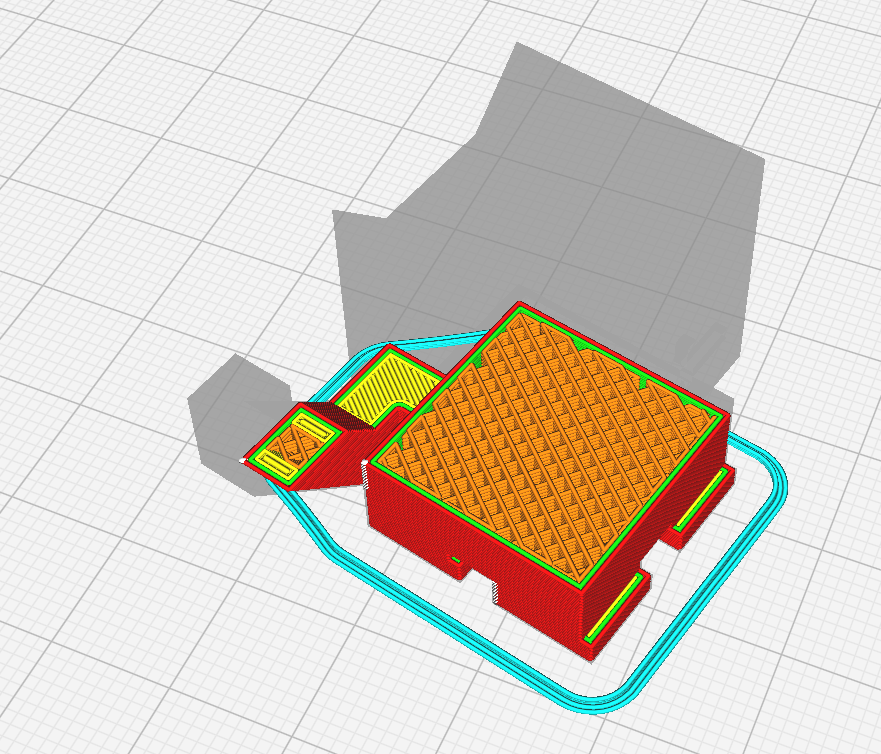

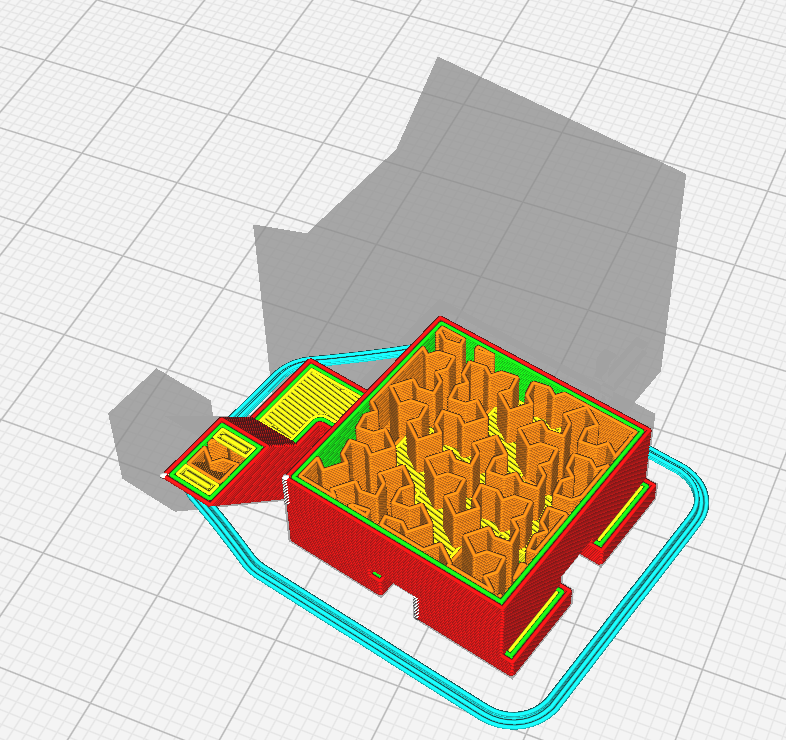

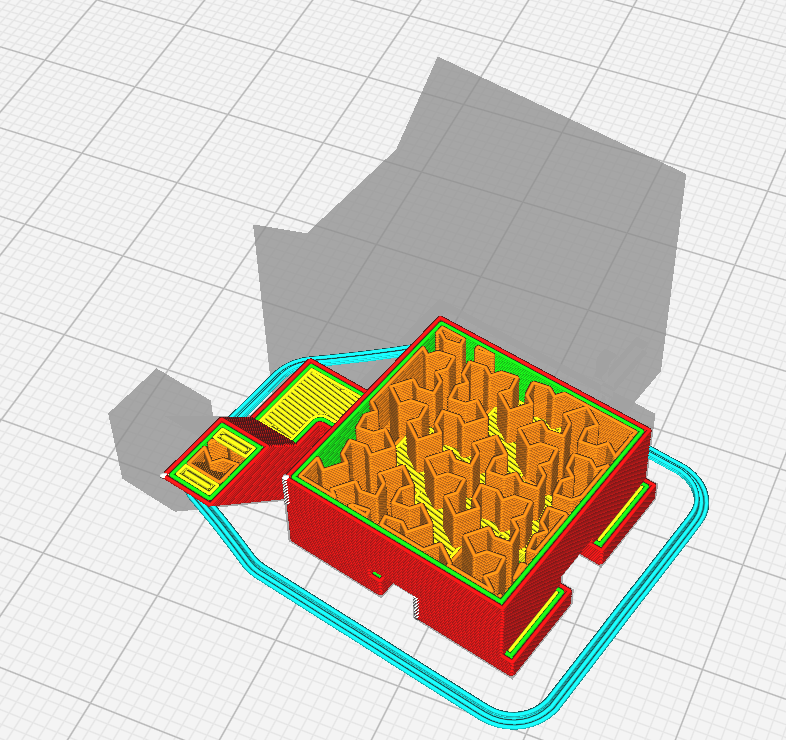

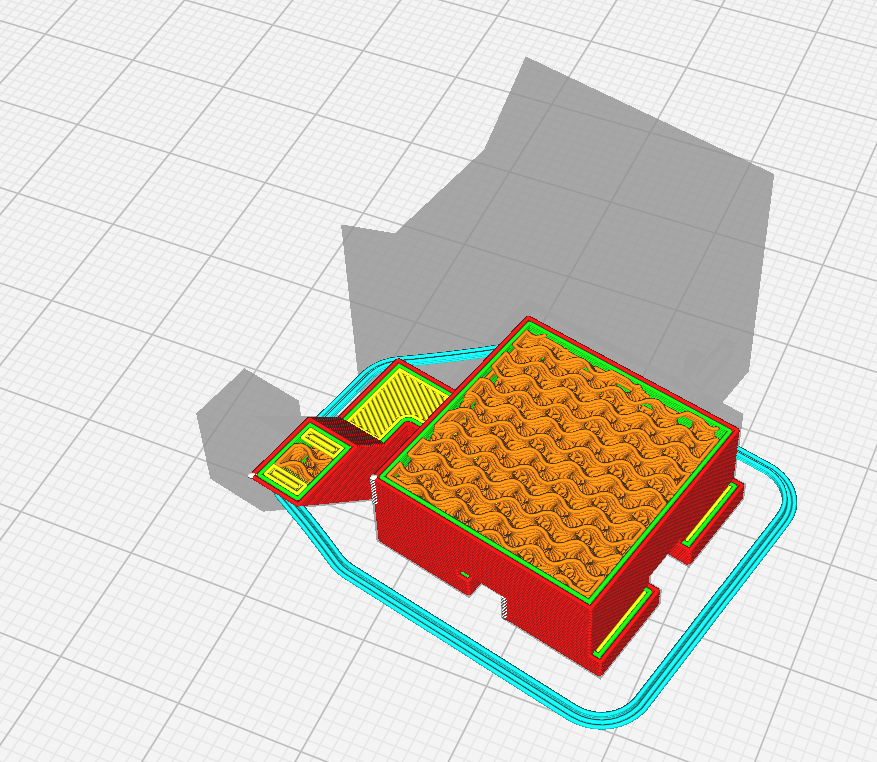

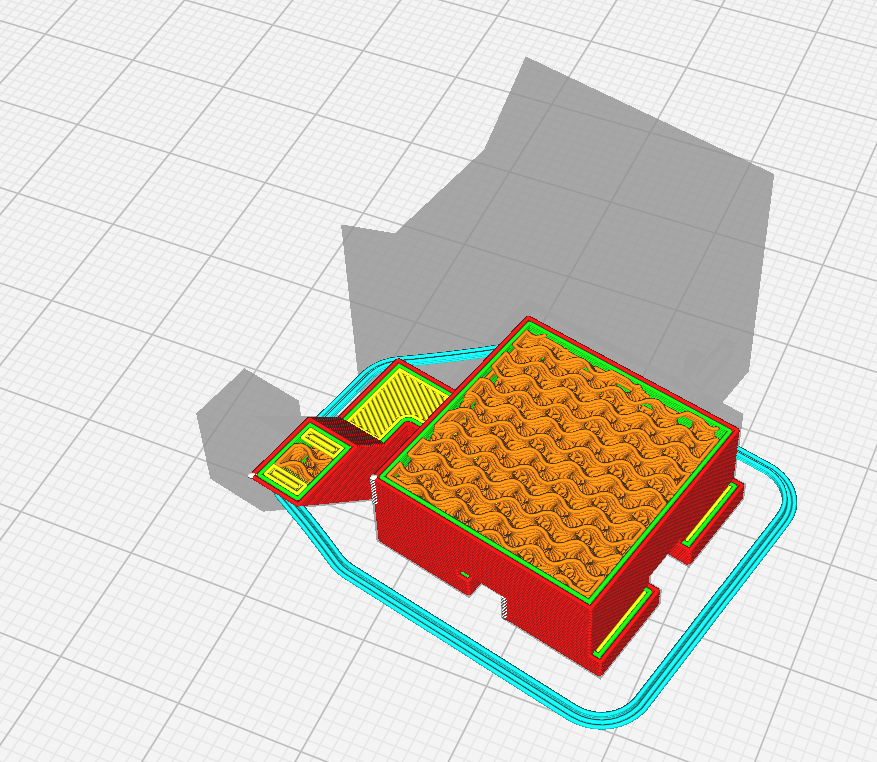

Normal creates sheets of support under your print, connected at top and bottom:

Tree creates branching circular structures to support overhangs in the model:

Normal is the recommended setting unless it creates particularly hard to remove sections with print trapped between support on all sides.

Placement designates where supports generate, and gives two options, Everywhere and Touching Buildplate.

Everywhere means any overhang will be supported, no matter where on the print it is.

Touching Buildplate will only support overhangs over the buildplate, and overhangs that have other bits of object below will not generate support.

It is recommended to use Everywhere when overhangs are present.

Adhesion helps prints stick to the print bed and avoid shifting and warping off of the bed. It is recommended to keep this setting selected for any print.

Many other specific settings can be tuned by clicking Show Custom however there are far too many to cover in this guide, so look to a more specific guide on the Cura Slicer for information on that.

Once you have your preferred settings set, move to the Slicing Files section.

Once you have set up your print how you want it, press the Slice button in the bottom right.

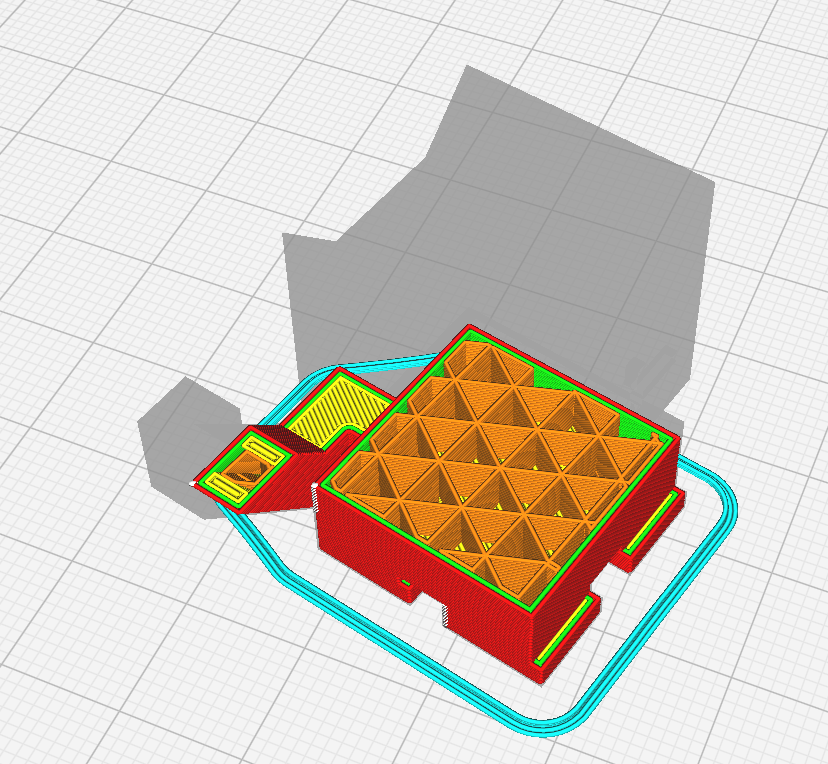

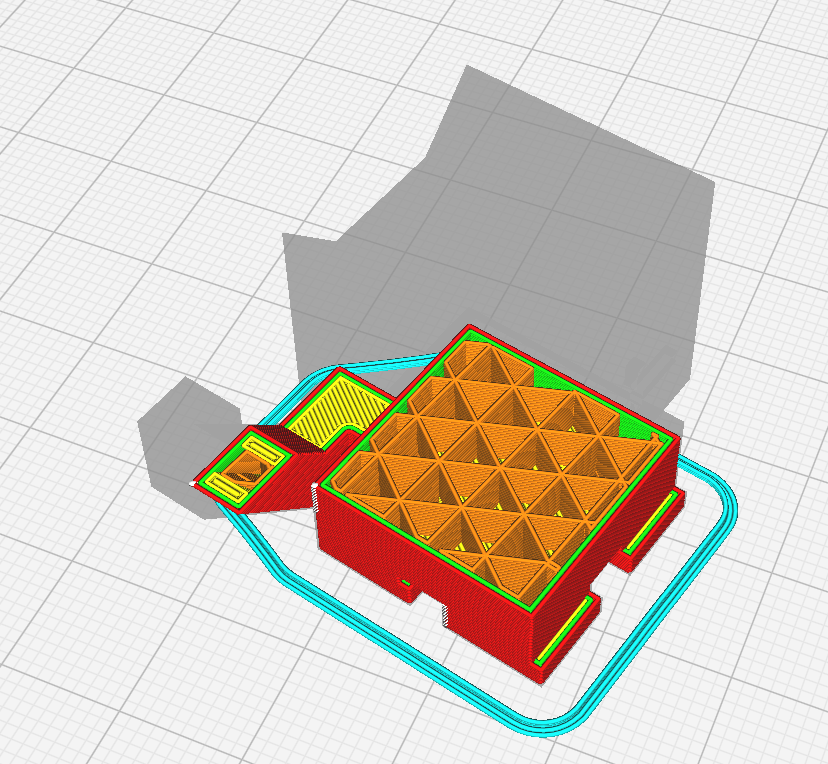

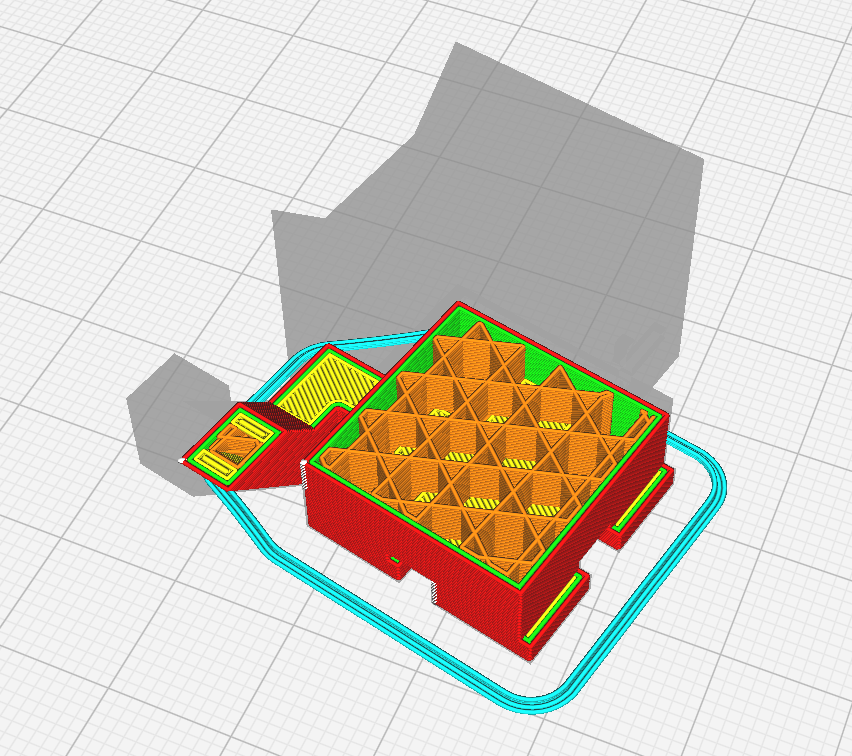

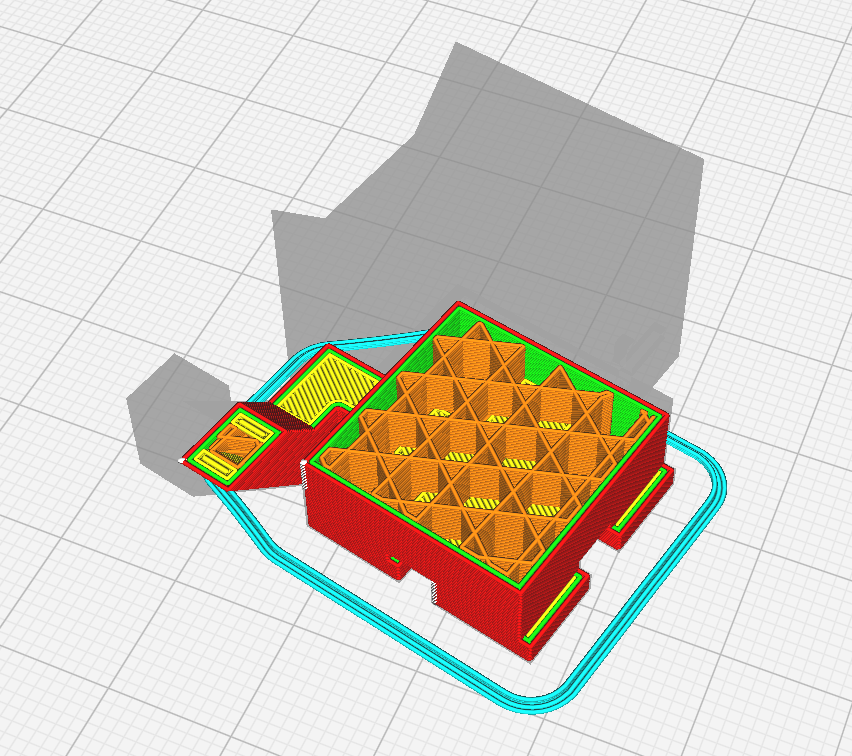

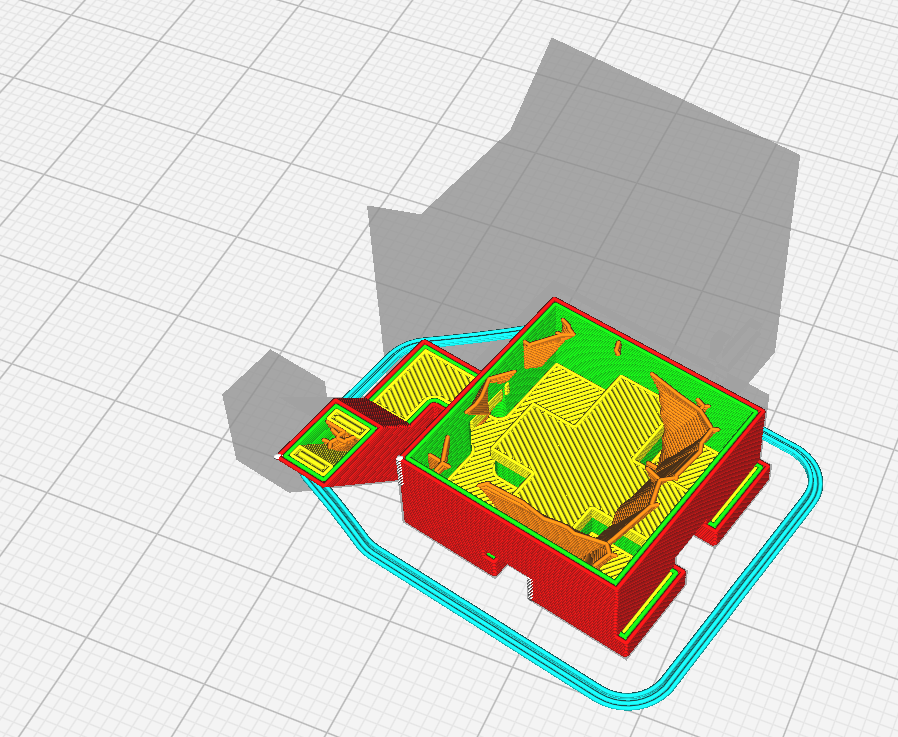

Once you do this, you will see a new tab appear, Preview. This allows you to look at the exact printing path of the printer.

Here you can use the slider on the right to move up and down the layers, showing each layer path individually, and then use the bottom slider to watch the exact movement path for that layer.

Once you have done this, move to the Transferring to printer section.

Once you have your gcode file, take the USB drive out of the printer and plug it into the computer. You can ignore any windows that pop up after doing this. Navigate back to UltiMaker Cura and look to the bottom right. If the button says Save To Removable Drive click it. If not, click the up arrow, then click Save To Removable Drive to make the button read Save To Removable Drive, then click the button.

Once you do this a saving progress bar will appear, and then a box that says File saved. You can then press the Eject button that appears there. Once the box reads Drive Successfully Ejected you can remove the USB stick.

Finally plug the drive back into the printer. Once you have done this move to the Printing section.

Once you plug the USB into the printer, you should be greeted with this image.

To print, hit the Print from USB button, then scroll until you see the file you wish to print. Press the file name and another menu will appear.

Check that the time, and two filament types match what you expect, and then press start print. Your file should then print! If the filament types do not match what is in the printer, go to the Changing Filament Section. If any other issues arise go to the Troubleshooting section.

Most errors with the UltiMaker will create an error message accompanied by the QR code. If this happens scan the QR code to find out how to fix the error.

The most common errors occur when:

The white silicone cover is not on the print heads: To fix this reinsert the silicone cover.

The printer thinks it does not have filament loaded but does: To fix hit the OK button and hit resume when it returns to the printing screen, the printer will figure out that it does in fact have filament.